Dadri, Gautam Buddha Nagar, Uttar Pradesh

- GST NO. : 09ARCPD4541L1ZS

Muffle Furnaces

Leading Manufacturers, Wholesaler, Trader and Importer of NST -1400 Degree C 40-Segment Muffle Furnace, NST 1100 Degree C Atmosphere Muffle Furnace, NST 1200 Degree C Muffle Furnace, NST 1400 Degree C Atmosphere Muffle Furnace, NST 1400 Degree C Max Controlled Atmosphere Muffle Furnace, NST 1600 Degree C 16x12x12 Inch 40-Segment Muffle Furnace, NST 1600 Degree C Atmosphere Muffle Furnace, NST 1600C High Temperature Microwave Sintering Furnace, NST 1700 Degree C 40-Segment Muffle Furnace, NST 1700 Degree C Atmosphere Muffle Furnace, NST 1700 Degree C Max Controlled Atmosphere Muffle Furnace, NST 1800 Degree C 7 x 6 x 6 Inch Muffle Furnace, NST AM180-V7X Vacuum Arc Melting Furnace, NST High Temperature Up To 1600 C Microwave Muffle Furnace, NST High-Vacuum High-Temperature Microwave Research Furnace, NST Laboratory 1100C Electric Muffle Furnace, NST Vacuum Molybdenum Furnace, NST-1400 Clifting Vacuum Atmosphere Elevating Lifting Furnace and Touch Screen Vertical Lab Planetary Ball Mill Machine from Gautam Buddha Nagar.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1400 Muffle |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Voltage | 230V |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Compliance | CE Certified |

| Electrical Requirements | 110-240VAC, 50/60Hz, Single Phase |

| Min. Working Temperature | Ambient |

| Max Vs Constant Working Temperature | 1400 Degree C (2552 Degree F) / 1300 Degree C (2372 Degree F) |

| Refractory Lining | Mitsubishi (Japan) High Quality 1600 Grade Fiber Alumina |

| Heating Element Type | Silicon Carbide (SiC) |

| Thermocouple Type | S |

| Temperature Controller | Shimaden FP93 (Japan) with 4 Programs and 40 Segments (ie. 4 X 10 Segments or 2 X 20 Segments) |

| Max Heating / Cooling Rate | < 15 Degree C (59 Degree F) / min |

| Temperature Precision | +/- 1 Degree C |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

1400°C 40-Segment Muffle Furnaces w/ PC Interface

NST-1400 Muffle muffle furnaces feature a chamber with Mitsubishi (Japan) high quality alumina fiber insulation and silicon carbide (SiC) heating elements. A double walled steel internal housing helps minimize heat loss to exterior surface.

Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results.

Features

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type S thermocouple.

- CE compliant

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller’s manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1100C Atmosphere |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Rated Power | 4KW, 9KW, 16KW |

| Certification | ISO 9001:2015 |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Dimension(L*W*H) | Size Can Be Customised |

| Compliance | CE Certified |

| Control Precision | +/- 10 Degree C |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

Heating element

- The hot end roughness D1 of the silicon molybdenum rod is 7mm, the average manufacturer adopts 6MM, the heating end is thick, the surface load of the rod is low, and the service life is long.

- It adopts hot bending technology, with uniform resistance and long service life

- The length of the cold end of the Lu is 210mm, 400X300X300 furnace is 260, the general manufacturer adopts 180mm, and the cold end has a low temperature.

- The surface oxidation of silicon molybdenum rod is compact and can better protect the silicon molybdenum rod.

Install air switch and leakage protector:

When an electric current or leakage, an empty meeting automatically disconnects.

Can connect with computer

This furnace is equipped with communication interface and software, can be directly through the furnace computer control of each parameter, and can be observed from the computer PV on the stove and SV temperature value and instrument operation, the actual temperature of the furnace curve drawing computer real time, and can keep the temperature data of each time, can call up at any time.

Chamber

Imported VS Chinese

- High quality high pure alumina polycrystalline fiber cured furnace with vacuum suction and filter molding.

- Adopt Japanese technology to form.

- The spacing and pitch of the resistance wire in the furnace are arranged according to the best thermal technology of Japan, and the temperature field is simulated by thermal software

- Using 4 weeks heating, the temperature is more balanced The furnace can not remove powder, heat insulation, high reflectivity and temperature balance, which is strong against heat and shrinkage

Optional UL certified electrical board (all imported electrical appliances approved by UL)

Trigger VS Soft start limited flow trigger Most of the manufacturers use the non – limited Xiamen botany trigger

- Phase shift trigger (with soft start and current limiting function)

- Current limiting function: no matter how the heating time is adjusted, the secondary current of our electric furnace after the transformer is limited to 170A, and the equipment is limited. Unlimited-flow triggers, if the heating rate is set wrong or too fast, The current is so large at low temperature that the device can trip or burn.

- Soft start function: the current will gradually increase when starting up, and the impact on the heating element will be small, which will help to prolong the life of the heating element

- Protection function: if the current exceeds the limiting current, the trigger will automatically cut off the trigger function to cut off the current protection furnace.

UL certified transformer

- The transformer cable is pure copper

- Small transformer

- Low temperature of transformer

The stainless steel tank of hydrogen atmosphere furnace is installed in the chamber of a stove or furnace a stainless steel tank, the tank oven door USES silicone O ring seal, in order to reduce O ring seal temperature in the furnace door is equipped with water cooling system, thermocouple, inlet valve, the valve installed on the tank, pressure gauge, etc; This furnace installation with hydrogen detector, burner, the combustion controller, alarm lights, torches, explosion-proof valve, etc., after gas after flow meter by chamber in and out, tail gas from the door of the oven after cooling water system. Can pass, argon, nitrogen, oxygen, hydrogen gases such as carbon monoxide, ammonia decomposition gas, &energy-saving equilibrium temperature field, the surface temperature is low, lifting speed, energy saving, clean furnace temperature is not easy to contaminated, universities, research institutes, industrial and mining enterprises do protect the sintering atmosphere, reducing atmosphere, skim the ideal product.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1200 Muffle |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Power | 110-240VAC,50/60Hz,Single Phase |

| Certification | ISO 9001:2015 |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Compliance | CE Certified |

| Min. Working Temperature | Ambient |

| Max. Working Temperature | 1200 Degree C (2192 Degree F) |

| Max. Constant Working Temperature | 1100 Degree C (2012 Degree F) |

| Refractory Lining | Mitsubishi (japan) High Quality 1500 Grade Fiber Alumina |

| Heating Element Type | Kanthal (Sweden) Resistance Coil Wire |

| Thermo Couple Type | K |

| Temperature Controller | Shimaden FP93 (japan) with 4 Programs and 40 Segments (ie. 4 X 10 Segments or 2 X 20 Segments) |

| Max Heating / Cooling Rate | < 15 Degree C (59 Degree F) / min |

| Temperature Accuracy | +/- 1 Degree C |

| CE Compliance | Yes |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST 1200°C Muffle Furnace w/ Kanthal (Sweden) Heating Elements

NST 1200°C Muffle muffle furnaces feature the famous Kanthal(Sweden) spiral wire coils embedded in Mitsubishi (Japan) high quality alumina fiber insulation. A double walled steel internal housing helps minimize heat loss to exterior surface.

Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results.

Features:

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type K thermocouple.

- CE compliant

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller’s manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1400C Atmosphere |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Dimension(L*W*H) | Size Can Be Customised |

| Compliance | CE Certified |

| Max. Temperature | 1400 Degree C |

| Heating Rate | ≤30 Degree C /min |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST-1400C Atmosphere has many advantages of uniform temperature field,low surface temperature,heating or cooling promptly and so on. it is the ideal atmosphere muffle furnace for atmosphere protection sintering,atmosphere reducing in Industry, Scientific research institutes, Universities, which offer Heating element of Sic and double layer housing,phase-shift trigger,controlled silicon. Operation system is Shimaden 40-segments digital controller imported from Japan. The chamber is made of Polycrystalline alumina fibre. There is wind cooling system between the double walled housing to help the furnace heat or cool promptly. Sealed housing,silicon gel sealed cover,sealed door with silicon gel gasket and water cooling system,gas float through flow meter,then come out from back side, there are many gas inlets and gas outlets on the furnace with burning mouth,which can pre-vacuum and pass H2,Ar,N2,O2,CO,NH3 and so on.

- Temperature controller: Shimaden FP93 40 programmable segments (Shimaden fp93 made in Japan), It can separate into 4,2,1 programs, ie. 4×10 segments. FP93 have 6 PID controls, different PID are used for low,middle,high temperature for precise control.Over-temperature and over-current protection, shutdown automatically when thermocouple is broken( it will shut down power when temperature is higher than 1420⁰ or thermocouples is broken, “ON” on the board is off and “OFF” is on)There is Fahrenheit (F) and Celsius (C) for option.With 485 communication interface: which can stop the furnace automatically.

- Cover opening protection system: overtravel-limit switch is installed to protect user, it will cut off power when the cover is opened.

- Chamber:it is imported from Japan, good performance of heat preservation, high reflectivity, even temperature field, good ability of anti thermal expansion and cold contraction.

- Heating elements:This furnace is installed with Sic to ensure uniform temperature field and long service life.

- Leakage protection function:the furnace is installed with leakage air switch, it will cut off power Automatically when electricity leak or current exceed rated current.

- Software controlling system:this furnace can control every parameter directly and observe PV

- and SV on the computer by communication interface and software, computer can draw and save actual heating curve, it is convenient to call these dates at any time.

- Controlling system: Power control: Chint; Controlled silicon:Germany Semikron 106/16E; Trigger:Phase-shift trigger

- Gas system:floating flow meter or digital flow meter is for option to control gas Speed.

- Vacuum system: Vacuum level can be 10-1 or 10-4 with German molecular pump. TW-1.5 vacuum pump is for option.Pre-vacuuming can help remove air in the chamber quickly.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1400C Atmosphere |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Warranty | One Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Dimension(L*W*H) | Size Can Be Customized |

| Compliance | CE Certified |

| Electrical Requirements | 208-240 V, 50/60Hz, Single Phase |

| heating Element & Thermo Couple Type | Silicon Carbide (SiC, Diameter 12-14mm) / S-Type |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST 1400°C Max Controlled Atmosphere Muffle Furnace w/ PC Interface

NST 1400 series controlled atmosphere furnaces feature a chamber with Mitsubishi (Japan) high quality alumina fiber insulation and SiC heating elements. A double walled steel internal housing helps minimize heat loss to exterior surface. Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results. All our furnaces are CE compliant.

The benefits of an controlled atmosphere furnace

An atmosphere furnace provides the perfect environment for various procedures in many laboratories, providing the controlled temperature and atmosphere specific projects require. The controlled atmosphere is desired to complete tasks that require exact temperatures with no room for error. This is the best way to ensure the successful outcome of your project because it is sealed tightly to ensure the proper environment.

Gases

One of the main components of the atmosphere furnace is the correct mixture of gases. The precise measurement of each gas is essential to the success of your project. You can use a separate chamber to mix the gases, which are then pumped into the furnace chamber where the work will be completed when they are done mixing. It is essential that the separate chamber that holds the gases does not receive any outside air because it could throw off the gas mixture and render your project useless.

Temperature

Proper temperature control is vital to the success of your project as well. Temperatures that are too high or too low will cause problems with the process and could cost your company a significant amount of money. Across International furnaces come with built-in 28-segment PID digital temperature controller for accurate monitoring and consistency.

Features

- Multiple gas inlets and outlets with stainless steel ball valves. Flow meter to control inbound and outbound gas flows. Outlets can be ignited to burn off gas.

- Furnace chamber is welded and oil leak tested to ensure air tightness. Furnace door is sealed with high temperature silicon gasket.

- Built-in stainless steel water-cooling panel protects door sealing gasket when furnace is under heavy use.

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type S thermocouple.

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller’s manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1600 Muffle |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Voltage | 230V |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Compliance | CE Certified |

| Electrical Requirements | 110-240 VAC, 50/60 Hz, Single Phase |

| Temperature Precision | +/- 1 Degree C |

| Max Heating / Cooling Rate | < 15 Degree C (59 Degree F) / min |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST 1600°C 16x12x12″ 40-Segment Muffle Furnace w/ PC Interface

NST-1600Muffle muffle furnaces feature a chamber with Mitsubishi (Japan) high quality alumina fiber insulation and molybdenum silicide (MoSi2) heating elements. A double walled steel internal housing helps minimize heat loss to exterior surface.

Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results.

Features:

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type B thermocouple.

- CE compliant

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller’s manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1600 C Atmosphere |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Dimension(L*W*H) | Size Can Be Customised |

| Compliance | CE Certified |

| Thermocouple | Type B |

| Heating Element | MoSi2 |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST-1600C Atmosphere has many advantages of uniform temperature field,low surface temperature,heating or cooling promptly and so on. it is the ideal atmosphere muffle furnace for atmosphere protection sintering,atmosphere reducing in Industry, Scientific research institutes, Universities, which offer Heating element of Sic and double layer housing,phase-shift trigger,controlled silicon. Operation system is Shimaden 40-segments digital controller imported from Japan. The chamber is made of Polycrystalline alumina fibre. There is wind cooling system between the double walled housing to help the furnace heat or cool promptly. Sealed housing,silicon gel sealed cover,sealed door with silicon gel gasket and water cooling system,gas float through flow meter,then come out from back side, there are many gas inlets and gas outlets on the furnace with burning mouth, which can pre-vacuum and pass H2,Ar,N2,O2,CO,NH3 and so on.

Features:

- Temperature controller: Shimaden FP93 40 programmable segments (Shimaden fp93 made in Japan), It can separate into 4,2,1 programs, ie. 4×10 segments.FP93 have 6 PID controls, different PID are used for low,middle,high temperature for precise control. Over-temperature and over-current protection, shutdown automatically when thermocouple is broken( it will shut down power when temperature is higher than 1420⁰or thermocouples is broken, “ON” on the board is off and “OFF” is on) There is Fahrenheit (F) and Celsius (C) for option. With 485 communication interface: which can stop the furnace automatically.

- Cover opening protection system: overtravel-limit switch is installed to protect user, it will cut off power when the cover is opened.

- Chamber:it is imported from Japan, good performance of heat preservation, high reflectivity, even temperature field, good ability of anti thermal expansion and cold contraction.

- Heating elements:This furnace is installed with Sic to ensure uniform temperature field and long service life.

- Leakage protection function:the furnace is installed with leakage air switch, it will cut off power Automatically when electricity leak or current exceed rated current.

- Software controlling system:this furnace can control every parameter directly and observe PV and SV on the computer by communication interface and software, computer can draw and save actual heating curve, it is convenient to call these dates at any time.

- Controlling system: Power control: Chint; Controlled silicon:Germany Semikron 106/16E; Trigger:Phase-shift trigger

- Gas system:floating flow meter or digital flow meter is for option to control gas Speed.

- Vacuum system: Vacuum level can be 10-1 or 10-4 with German molecular pump. TW-1.5 vacuum pump is for option.Pre-vacuuming can help remove air in the chamber quickly.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Certification | ISO 9001:2015 |

| Voltage | AC 220 Plus/minus 10V; 50Hz/60Hz |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Conditon | New |

| Model Number | NST-Microwave 1600 |

| Compliance | CE Certified |

| Rating Power | 4.0 KW |

| Microwave Output Power | 0.2-1.40 Kw Continuously Variable |

| Microwave Frequency | 2.45GHz Plus/Minus 25 MHz |

| Max. Sintering Temperature | 1600 Celsius Degree |

| Temperature Measuring Way | IR Thermometer |

| Temperature Range | 250 Celsius Degree -1650 Celsius Degree. |

| Atmosphere System | Air |

| Max Loading Space | 100x100x40mm (LxWxH) |

| Cooling | Water, 0.8 – 1m3/h at Pressure > 0.15MPa |

| Cycle Cooling Water Total Hardness | Less Than 60mg/L |

| Microwave Leakage | < 1mW/cm2 (Safety Standard < 5mW/cm2) |

| System Outside Dimension | 750 x 750 x 660mm (LxWxH) |

| Payment Terms | L/C, T/T, Western Union |

| Delivery Time | 20 Days |

Preferred Buyer From

| Location | Anywhere in India |

NST 1600C High Temperature Microwave Sintering Furnace

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1700 Muffle |

| Brand Name | NST |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Automation Grade | Automatic |

| Application | Laboratory |

| Certification | ISO 9001:2015 |

| Voltage | 320V-420V |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Compliance | CE Certified |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST 1700°C 40-Segment Muffle Furnace w/ PC Interface

NST-1700 Muffle furnaces feature a chamber with Mitsubishi (Japan) high quality grade 1800 alumina fiber insulation and molybdenum silicide (MoSi2) heating elements. A dual-wall steel housing helps minimize heat loss to exterior surface.

Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results.

Features

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type B thermocouple.

- CE compliant

Safety

Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller’s manual) or when the thermocouple is broken or malfunctions.

Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1700C Atmosphere |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Temperature Accuracy | +/- 1 Degree C |

| Dimension(L*W*H) | Size Can Be Customized |

| Compliance | CE Certified |

| Max. Temperature | 1700 Degree C |

| Constant Temperature | 1650 Degree C |

| Thermocouple | Type B |

| Heating Element | 1800 MoSi2 Rod |

| Heating Rate | ≤20 Degree C /min |

| Recommended Heating Rate | ≤10 Degree C/min |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST 1700°C Atmosphere Muffle Furnace

NST-1700C Atmosphere has many advantages of uniform temperature field,low surface temperature,heating or cooling promptly and so on. it is the ideal atmosphere muffle furnace for atmosphere protection sintering,atmosphere reducing in Industry, Scientific research institutes, Universities, which offer Heating element of Sic and double layer housing,phase-shift trigger,controlled silicon. Operation system is Shimaden 40-segments digital controller imported from Japan. The chamber is made of Polycrystalline alumina fibre. There is wind cooling system between the double walled housing to help the furnace heat or cool promptly. Sealed housing,silicon gel sealed cover,sealed door with silicon gel gasket and water cooling system,gas float through flow meter,then come out from back side, there are many gas inlets and gas outlets on the furnace with burning mouth, which can pre-vacuum and pass H2,Ar,N2,O2,CO,NH3 and so on.

Features:

- Temperature controller: Shimaden FP9340 programmable segments (Shimaden fp93 made in Japan), It can separate into 4,2,1 programs, ie. 4×10 segments. FP93 have 6 PID controls, different PID are used for low,middle,high temperature for precise control.Over-temperature and over-current protection, shutdown automatically when thermocouple is broken( it will shut down power when temperature is higher than 1420⁰or thermocouples is broken, “ON” on the board is off and “OFF” is on)There is Fahrenheit (F) and Celsius (C) for option.With 485 communication interface: which can stop the furnace automatically.

- Cover opening protection system: overtravel-limit switch is installed to protect user, it will cut off power when the cover is opened.

- Chamber:it is imported from Japan, good performance of heat preservation, high reflectivity, even temperature field, good ability of anti thermal expansion and cold contraction.

- Heating elements:This furnace is installed with Sic to ensure uniform temperature field and long service life.

- Leakage protection function:the furnace is installed with leakage air switch, it will cut off power Automatically when electricity leak or current exceed rated current.

- Software controlling system:this furnace can control every parameter directly and observe PV and SV on the computer by communication interface and software, computer can draw and save actual heating curve, it is convenient to call these dates at any time.

- Controlling system: Power control: Chint; Controlled silicon:Germany Semikron 106/16E; Trigger:Phase-shift trigger

- Gas system:floating flow meter or digital flow meter is for option to control gas Speed.

- Vacuum system: Vacuum level can be 10-1 or 10-4 with German molecular pump. TW-1.5 vacuum pump is for option.Pre-vacuuming can help remove air in the chamber quickly.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand | NST |

| Condition | New |

| Power Source | Electric |

| Certification | ISO 9001:2015 |

| Warranty | One Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Input Voltage | 220V |

| Thermocouple Type | B |

| Model Number | NST-1700C Atmosphere |

| Dimension(L*W*H) | Size Can Be Customized |

| Compliance | CE Certified |

| Electrical Requirements | 208-240V, 50/60Hz, Single Phase |

| Heating Element Type | Molybdenum Silicide (mosi2, Diameter 7mm) |

| Inlet/Outlet | 1/4 Inch Hose Barb with 1/4 Inch BSPT (British Standard Pipe Thread) |

| Positive Pressure | Not to Exceed 0.02 Mpa / 150 Torr / 3 Psi |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST 1700 Series controlled atmosphere furnaces feature a chamber with Mitsubishi(Japan) high quality alumina fiber insulation and MoSi2 heating elements. A double walled steel internal housing helps minimize heat loss to exterior surface. Furnace operation is controlled byShimaden(Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results. All our furnaces are CE compliant.

The benefits of an controlled atmosphere furnace

An atmosphere furnace provides the perfect environment for various procedures in many laboratories, providing the controlled temperature and atmosphere specific projects require. The controlled atmosphere is desired to complete tasks that require exact temperatures with no room for error. This is the best way to ensure the successful outcome of your project because it is sealed tightly to ensure the proper environment.

Gases

One of the main components of the atmosphere furnace is the correct mixture of gases. The precise measurement of each gas is essential to the success of your project. You can use a separate chamber to mix the gases, which are then pumped into the furnace chamber where the work will be completed when they are done mixing. It is essential that the separate chamber that holds the gases does not receive any outside air because it could throw off the gas mixture and render your project useless.

Temperature

Proper temperature control is of great importance to the experimental project. Temperatures that are too high or too low can cause problems in the process and may incur additional costs.Our furnaces come with built-in 28-segment PID digital temperature controller for accurate monitoring and consistency.

Features:

- Multiple gas inlets and outlets with stainless steel ball valves. Flow meter to control inbound and outbound gas flows. Outlets can be ignited to burn off gas.

- Furnace chamber is welded and oil leak tested to ensure air tightness. Furnace door is sealed with high temperature silicon gasket.

- Built-in stainless steel water-cooling panel protects door sealing gasket when furnace is under heavy use.*Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- CE compliant

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller’s manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Ultimate vacuum level for furnaces is around 100 Pa with all flange connections, and 1000 Pa with hose barb connections. Please keep in mind that our atmosphere furnaces are NOT designed to be vacuum furnaces, the vacuuming part is mainly for users to pre-vac the chamber, before putting in inert or other protective gases.

Temperature Control:

- Controller: Shimaden fp93 (Japan) with 4 programs and 40 segments (ie. 4 x 10 segments or 2 x 20 segments).

- Maximum heating rate: 15°C per minute

- Minimum temperature: 300°C (recommend at least 800°C for longer heating element life)

- Maximum/constant temperatures: 1700°C/1600°C (Depends on gas environment)

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-1800 Muffle |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Type | Muffle Furnace |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Chamber VS Usable Size (DxWxH) | 7 x 6 x 6 Inch (0.15 Cubic Foot) / 5 x 5 x 5.5 Inch |

| Max. Working Temperature | 1800 Degree C (3272 Degree F) for less than 5 hours |

| Refractory Lining | Mitsubishi (japan) High Quality Grade 1900 Fiber Alumina |

| Heating Element | Kanthal (Sweden) Grade 1900 Molybdenum Silicide (MoSi2), 6 installed |

| Thermocouple Type | B or PtRh40-PtRh20 (Optional) |

| Min. Working Temperature | 300 Degree C (572 Degree F) |

| Max. Constant Working Temperature | 1700 Degree C (3092 Degree F) or 1750 Degree C with PtRh40-PtRh20 (Optional) |

| Max Heating / Cooling Rate | 1200 Degree C and Below: <30 Degree C/min, 1200 Degree C+: < 15 Degree C/min |

| Temperature Accuracy | +/- 1 Degree C |

| Input | 208-240v AC, 50/60Hz, Single Phase |

| Maximum Output | 4.5 kW |

| Unit/shipping dimensions (WxDxH) | 24 x 22 x 34 Inch / 30 x 29 x 42 Inch |

| Shipping Weight | 300 Lb |

| CE Compliance | Yes |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST 1800°C 7x6x6″ Muffle Furnace w/ Kanthal (Sweden) Heating Element

NST -1800Muffle furnaces feature a chamber with Mitsubishi (Japan) high quality grade 1900 alumina fiber insulation and the famous Kanthal (Sweden) molybdenum silicide (MoSi2) heating elements. A dual-wall steel housing helps minimize heat loss to exterior surface.

Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results.

Features:

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type B thermocouple.

- CE compliant

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller’s manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Temperature Controller: Shimaden fp93 (Japan) with 4 programs and 40 segments (ie. 4 x 10 segments or 2 x 20 segments) Eurotherm temperature controller (optional)

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Power | Customizable,Default 18 KW (Three-Phase 380V) / 13 KW (AC220V) |

| Certification | CE Certified |

| Weight | 12 Kg |

| Warranty | 1year |

| Country of Origin | India |

| Supply Voltage | AC380V (Three Phase) or AC220V, 50Hz |

| Chamber Material | Stainless Steel |

| Cooling Method | Water-cooled Chamber, Water-cooled Electrode, Water-cooled Copper Crucible |

| Chamber Size | O.D φ200mm × H.180mm |

| Observation Window Diameter | 40mm |

| Water-cooled Connector | 1/4-Inch Quick Plug Interface |

| Vacuum Interface | KF16 Flange |

| Vacuum Pump | Rotary Vane Pump; Molecular Pump Set is Optional |

| Intake Interface | 1/4-inch Quick Plug Interface |

| Intake Valve | Stainless Steel Needle Valve |

| Vacuum Gauge | 2.5-stage Pointer Vacuum Gauge |

| Overall Dimension | 600mm × 500mm × 800mm(Without Vacuum System and External Power Supply) |

| Model Number | NST AM180-V7X |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

This product is a small vacuum arc melting furnace with tungsten electrodes and water-cooled copper crucible. The equipment melting temperature can exceed 3000℃, and the temperature is reduced rapidly. The equipment adopts stainless steel water-cooled chamber and is equipped with a quartz observation window to observe the sample melting condition, which is very suitable for sample melting and heat treatment, phase diagram research. During smelting, the metal is placed in the water-cooled copper crucible. According to the process requirements, the furnace can be filled with high-purity inert protective gas, and the high-temperature plasma generated by the arc is used to melt the metal. Multi-station copper crucible can be used for a variety of small metal (about 3g ~ 5g per station) smelting in sequence, with the side control lever for tilting and rotating metal ingots after smelting. There is a larger cavity in the middle of the copper crucible for mixed smelting of the alloy (which can hold about 25g). The smelting furnace is also equipped with a vacuum suction casting mold. The user can replace and install it by simple tools. After replacement, the vacuum suction casting function can be realized. The cylindrical metal sample can be made to facilitate subsequent cutting, clamping and analysis operations.

Vacuum arc melting furnace features:

The device has the advantages of small size, stable performance, simple operation, comprehensive functions and convenient use, and is very suitable for laboratory research on small doses of metal samples.

Crucible

- Water-cooled copper crucible with 7 cavities, 6 cavities φ25mm×8mm,the large working cavity φ40mm×12mm can be used for mixed smelting alloy.

- Vacuum suction casting mold crucible, φ13mm×33mm.

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-Microwave 1600, TMAX-Microwave1600 |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Voltage | AC 220 Plus/Minus 10V; 50Hz/60Hz |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Compliance | CE Certified |

| Rating Power | 4.0 Kw |

| Microwave Output Power | 0.2-1.40 Kw Continuously variable |

| Microwave Frequency | 2.45GHz Plus/Minus 25 MHz |

| Max. Sintering Temperature | 1600 Celsius Degree |

| Temperature Measuring Way | IR Thermometer |

| Temperature Range | 250 Celsius Degree -1650 Celsius Degree. |

| Temperature Accuracy | Plus/Minus 0.5% |

| Atmosphere System | Air |

| Max Loading Space | 100 x 100 x 40mm (LxWxH) |

| Cooling | Water, 0.8 – 1m3/h at Pressure > 0.15MPa |

| Cycle Cooling Water Total Hardness | Less Than 60mg/L |

| Microwave Leakage | < 1mW/cm2 (Safety Standard < 5mW/cm2) |

| System Outside Dimension | 750 x 750 x 660mm (LxWxH) |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

High Temperature Up To 1600C Microwave Muffle Furnace

- Microwave heating.

- Temperature up to 1600 degree.

- Heating speed up to 50 degree per minute.

- No pollution to material.

Application Field:

- Claiming / synthesis of powder or particle materials:

- Electronic ceramic powders: barium titanate, barium-strontium titanate, strontium titanate, barium zirconate titanate;

- Lithium ion battery anode materials: lithium cobaltoxide, lithium manganate;

- Various colorants, glaze material, inorganic pastel;

- Alumina, magnesium oxide, zinc oxide, manganese dioxide, manganous-manganicoxide, zirconia, ammonium metavanadate, vanadium pentoxide, titanium dioxide, zinc carbonate, manganese carbonate, aluminum hydroxide, magnesium hydroxide, lithium cobaltoxide, zinc ferrite, Tri-chromatic rare earth fluorescent powder (Red), cement.

Synthesis / sintering of devices:

- Electronic ceramics: Piezoresistive element, thermistor, piezoceramics, microwave medium ceramics;

- Magnetic materials: hard magnetic, Ni-Zn, gyromagnet ferrites;

- Honeycomb ceramics, daily-use ceramics and glass ware;

- Oxide ceramics and refractory materials: alumina, zirconia, magnesium oxide and other oxide composites;

- Incineration, cremation, scaling loss experiments

Protection and Safety: Anode over voltage, anode over current, anode power surpass, electromagnet watchdog, magnetron temperature, external interlock. Control System: PLC (18 sections of temperature control), embedded system connected to laptop via USB, with data storage and printing functions.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Country of Origin | India |

| Model Number | NST-HAMiLab-HV3 |

| Compliance | CE Certified |

| Warranty | Two Years Limited Warranty with Lifetime Technical Support |

| Power Supply | 380±10V/50Hz; |

| Rated Power | 15 Kw |

| Microwave Output Power | 0.3~2.85 Kw Continuously Adjustable |

| Microwave Frequency | 2.45GHz ± 25MHz |

| Maximum Use Temperature | 1600 Degree C |

| Temperature Measurement Method | Infrared Thermometer (American Leitai) |

| Temperature Range | 450 Degree C ~ 2250 Degree C |

| System Accuracy | ± (0.3% of Measurement Reading + 1 Degee C); |

| Static Vacuum Degree | ≤10-3Pa |

| Loading Space | φ90×100 mm |

| Circulating Cooling Water Flow Rate | ≥1.5m3/h |

| Circulating Cooling Water Pressure | ≥ 0.15MPa |

| Circulating Cooling Water Inlet Water Temperature | 5~30 Degree C |

| The Total Hardness of Circulating Cooling Water | <60mg / L (Can Be Replaced By Daily Tap Water) |

| Microwave Leakage | <2000uw/cm2 |

| Equipment Dimensions | 1700 × 2260 ×2200 mm (Length × Width × Height) |

| Payment Terms | L/C, T/T |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Anywhere in India |

NST-High-vacuum High-temperature Microwave Research Furnace For Lab

The high-vacuum, high-temperature microwave research furnace is typically used for synthesis or sintering of magnetic materials, ceramics, metal powders.

Control system: Embedded system control mode, can be connected to PC, can realize data storage and printing function; can set multiple process curves, each curve can set 40 process parameters; with automatic / manual operation dual function;

Bring a protective atmosphere system;

| Business Type | Manufacturer, Exporter, Supplier |

| Model Number | NST-DSP-KF1100 |

| Brand Name | NST |

| Driven Type | Electric |

| Condition | New |

| Certification | ISO 9001:2015 |

| Voltage | Ac 110V Or AC 220V 50/60 Hz — Please Select The Voltage In The Option Bar |

| Warranty | 1yrs, One Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Compliance | CE Certified |

| Max. Heating Rate | 30 Degree C /min |

| Temperature Accuracy | +/- 1 Degree C |

| Heating Elements | Fe-Cr-Al Alloy Doped By Mo |

| Thermocouple | K Type |

| Overall Dimensions | 250x200x380 (DxWxH) |

| Net Weight | ~ 8 Kg |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

NST 1100°C Compact Muffle Furnace (4x4x4″,1.0L) with Programmable Controller

NST-DSP-KF1100 is a CE certified compact muffle furnace that offers high purity fibrous alumina chamber, gas inlet and outlet ports and a 30-segment, programmable temperature controller, and the furnace is with UL Certified electric components. It is the ideal muffle furnace for preparing small-sized sample using temperatures up to 1100oC in material research and dental labs with maximum energy saving. In addition, the compact furnace can be placed into a glove box to sinter samples in a vacuumed or controlled atmosphere.

Operating Temperature

- 1000°C max continuously

- 1100°C max for an hour

- 1200°C max for 30 minutes

Chamber Size

- Size: 4″x4″x4″ or 100x100x100 mm

- Capacity: 65 cubic-inch or 1 liter

Power

- 110V version: 950 W (15A Fuse) ( power cord is included )

- 220V version: 1.2KW(10A Fuse)

Temperature Controller

- PID automatic control and auto-tune function.

- 30 programmable segments for precise control.

- Built in protection for the over-heating and broken thermocouple.

- Large digital control panel (48 x 96 mm) for easy operation.

Application Notes

With the small footprint, low weight and low power requirement, it can be easily accommodated in a glove box and heat treat samples under protective gas.

Warnings

- Toxic or explosive gases are not recommended for use with this furnace without necessary safety controls and supervision. Please put furnace into fume hood for better safety.

- Small cracks may appear on the surface of the refractory ceramics over extended use. This is a normal occurrence and the cracks may be repaired with alumina coating.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Material | Metal |

| Driven Type | Electric |

| Color | Grey & Blue |

| Condition | New |

| Automation Grade | Automatic |

| Application | Laboratory |

| Certification | ISO 9001:2015 |

| Country of Origin | India |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

The equipment features and the main purpose

Basic principles and uses In the case of vacuum or atmosphere protection of the material for non-polluting heat treatment equipment can be nitrogen argon hydrogen and other atmosphere sintering. Mainly used in high temperature atmosphere sintering high temperature vacuum sintering transparent ceramics and other materials sintering.

The structure of the composition

Furnace body furnace lid bottom vacuum system control system cooling system heating body and insulation screen.

The structure that

- The furnace vertical shell its inner and outer are made of 304 stainless steel cylinder the outer mirror polished. Inside and outside the tube and the front and rear flange welded into a whole the furnace body with electrode holes suction holes vent holes thermocouple holes infrared holes and observation holes the interface materials are stainless steel.

- The lid from inside and outside the head and flange welding the middle of the water can be cooled the lid open device.

- The bottom the inside and outside the head and flange composition the middle of the water cooling the lower part of the filling and discharging holes fixed in the lower part of the furnace with electrode extraction device.

- Heating body and insulation screen heating elements made of high purity film effectively increase the radiation area to ensure uniformity of the temperature zone. The bottom of the insulation screen with a tungsten plate the other using the template and stainless steel plate production.

- The vacuum system mainly by the direct pump molecular pump or diffusion pump pneumatic baffle valve pneumatic shut-off valve digital composite vacuum gauge vacuum pipe bleed valve bracket and other components; vacuum pipe and pump between Metal corrugated hose quick connector connection (slow vibration).

The control system

A computer automatic control system (optional)

- Automatic PLC flat panel touch computer control (XP) system you can manually switch automatically. Features are as follows

- The control system software is developed by our company man-machine interface operating system picture-friendly simple operation fast running real-time monitoring of the furnace conditions the system is stable and reliable.

- Software color simulation screen display industrial grade Tablet PC fast response anti-interference ability temperature display and vacuum valve control are integrated analog screen operation.

- The device can adopt the temperature curve power curve vacuum curve water temperature curve air pressure curve and sintering time curve user-friendly analysis based on historical curve sintering process. Data can automatically generate excel file through the usb interface test.

- The temperature control method for the following thermocouple 1700 ℃ temperature control more than 1700 ℃ infrared instrument automatic control high and low temperature automatic conversion.

- Communication interface such as RS232 RS422 CAN LAN USB etc. easy and other equipment networking applications. Software control interface visualization can dynamically display the workflow convenient and intuitive.

- The software free upgrade for life.

Standard configuration manual instrument automatic temperature control 1700 ℃ below the thermocouple temperature control more than 1700 ℃ infrared instrument automatic control high and low temperature automatic conversion.

Water cooling system the furnace the upper and lower end of the cover with water-cooled structure of the form in and out of the water main pipe installed on the hydraulic relay and pressure gauge while the control cabinet connected to the abnormal state alarm. Can qualitatively observe the water flow size of each waterway. The entire water cooling system to ensure.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Color | Blue |

| Condition | New |

| Certification | ISO 9001:2015 |

| Voltage | 220V |

| Warranty | Two Years Limited Warranty With Lifetime Technical Support |

| Country of Origin | India |

| Model Number | NST-1400C Lifting |

| Dimension(L*W*H) | Size Can Be Customised |

| Compliance | CE Certified |

| Phase | Single |

| Heating Element | Silicon Carbide Rod |

| Trigger | Phase-Shift Trigger |

| Power Control | Chint |

| Controlled Silicon | Germany Semikron 106/16E |

| Payment Terms | L/C, T/T, Western Union |

| Delivery Time | 15 Days |

Preferred Buyer From

| Location | Anywhere in India |

THE VACUUM ATMOSPHERE LIFTING FURNACE FOR SILICON CARBIDE HEATING ELEMENTS, USES the three layers of shell structure and the Japanese island of 40 program temperature control system, electric phase-shifting trigger, thyristor control, furnace using 1600 type of polycrystal alumina fibre materials imported from Japan, between the furnace shell is equipped with air cooling system, can rise quickly cooling, &energy-saving equilibrium temperature field, low surface temperature and elevating temperature rate quickly, the advantages of energy saving, convenient take material, don’t need a crucible tongs stretch into the furnace, suitable for high temperature material taking and vacuum sintering in high temperature annealing is colleges and universities, research institutes, industrial and mining enterprises do powder sintering, ceramic sintering, glass melting, high temperature experiment, the ideal product quality inspection.

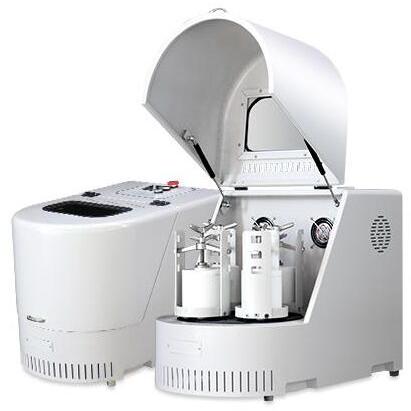

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Power | 750 W |

| Certification | ISO 9001:2015 Certified |

| Voltage | 220V |

| Type | Metal Milling |

| Warranty | 1year |

| Country of Origin | India |

| Model | NST-2T |

| Operation Mode | Two or four mill jars can be used for each grinding |

| Drive Mode | Gear drive or belt drive |

| Output Granule | Smallest granularity can be achieved to 0.1μm |

| Payment Terms | L/C, T/T, Western Union |

Preferred Buyer From

| Location | Anywhere in India |

PLANETARY BALL MILLS are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes. The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times.