Dadri, Gautam Buddha Nagar, Uttar Pradesh

- GST NO. : 09ARCPD4541L1ZS

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Country of Origin | India |

| Ultimate Pressure | ≤2.0×10-5 Pa |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

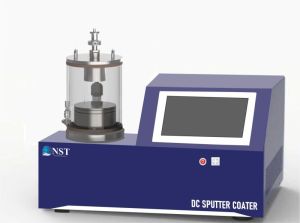

Product Details

ORGANIC AND INORGANIC EVAPORATION COATER adopts linear structure and is mainly composed of two organic material growth chambers which are connected by gate valves. One of the two growth Chambers is reserved for the butt joint interface with the glove box, which can complete the transfer of substrates between two independent film preparation systems. The organic material growth chamber mainly consists of vacuum chamber assembly, organic evaporation source, thermal resistance evaporation boat, sample transfer device, sample platform, film thickness monitor, vacuum chamber lighting device, baking device and so on.

Technical Specifications

| Vacuum chamber | Two D-shaped vacuum chamber, size: aboutΦ450×H750; Two vacuum chamber of the vacuum system configuration, extreme pressure, vacuum recovery time, thermal resistance evaporation boat and power supply, the film thickness monitor, vacuum chamber lighting equipment, baking equipment, sample platform configuration , The above configuration is the same as the technical parameters | |

| Vacuum system configuration | Japanese cryopump, oil-free vortex dry pump and electromagnetic valve, compound digital-displayed vacuum measurement auge and meter, valves etc. | |

| Ultimate pressure | ≤2.0×10-5 Pa | |

| vacuum recovery time | Reach 1×10-4 Pa in 40 mins | |

| Electric magnetic coupling sample transfer device | Vacuum chamber 1 | It adopts magnetic coupling line motion delivering device and is driven by stepper motor, It is equipped with remote manual control box to control straight forward and backward |

| Organic evaporation source and power | Vacuum chamber 1 | 9 new model OEL sublimation evaporation source, each filled with 10CC evaporation material, room temperature-800℃: 7; room temperature-1000℃: 2; evaporation source power: 4 |

| Vacuum chamber 2 | 6 new model OEL sublimation evaporation source, each filled with 10CC evaporation material, room temperature-800℃: 6; room temperature-1000℃: 2; evaporation source power: 4 | |

| Heat resistance evaporation boat and power | New model evaporation boat: 2 (heat resistance evaporation boat); digital heat resistance evaporation power: 1, with fine adjustment function (0.1A); aluminum coated special purpose box evaporation boat: 2; metal evaporation boat: 10; evaporation source baffle: 2. | |

| Film thickness monitor | Thickness resolution ratio | Non-uniformity: 0.0133Å/measure; 50 samples average: 0.002Å/measure |

| Velocity resolution ratio | Non-uniformity: 0.0133angstrom per second; 50 samples average: 0.02 angstrom per second | |

| Precision | 0.03HZ/measure, 2ppm | |

| Speed | Measuring 10 times per second | |

| Vacuum chamber lighting device | LED lighting outside chamber, to prevent film coating contaminate lighting | |

| Baking device | A method of baking in a vacuum outdoor baking strip | |

| Sample table | Sample size | Load one 100×100mm or 50×50mm substrate |

| Mode of motion | Power driven lifting, rotatable, rotating speed 0-30rpm, rotating speed adjustable | |

Looking for "Nst Organic and Inorganic Evaporation Coater" ?

Explore More Products