Dadri, Gautam Buddha Nagar, Uttar Pradesh

- GST NO. : 09ARCPD4541L1ZS

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Driven Type | Electric |

| Color | Blue |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

Condition

New

Certification

ISO 9001:2015

Voltage

220V

Warranty

1yrs, One Year Limited With Lifetime Support

Country of Origin

India

Maximum Temperature for Each Heater

≤ 800 Degree C

Thermal Couple

Two K-type Thermal Couples are Installed On Top and Bottom Heaters Separately

Working Voltage

208 – 240VAC, Single Phase, 50A Air Breaker

Power Requirement

10 kW Total

Payment Terms

L/C, T/T, Western Union

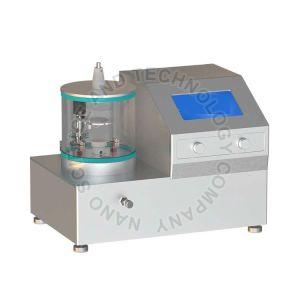

TWO ZONES CSS FURNACE WITH ROTATING WAFER HOLDER is heated by two group of halogen heaters (Top and Bottom) separately with max. 10ºC/s heating rate. The top sample holder is rotatable to achieve high uniformity coating. It is an excellent tool to research new generation thin film for solar cells, such as CdTe, Sulfide, and Perovskite solar cell.

Technical Specifications

| Furnace structure | Furnace, two temperature controllers, two-channel gas flowmeters are integrated into a mobile aluminum alloy frame. The chamber is made of high purity fused quartz tube with dimesion of 11″ OD/10.8″ ID×9″ H. The vacuum flanges are made of Stainless Steel 316 and lifting by electric motor. Two 5″×5″ IR heating plates and the spacing are adjustable . Top sample holder is rotatable at the speed 0-7 RPM. |

| Vacuum Flanges | Top Flange with one KFD-25 vacuum port and one gas outlet (1/4″ pipe required) can slide up or down manually to load and unload substrate and evaporated material easily. Bottom flange has one KFD-25 vacuum port with one gas nlet (1/4″ pipe required) with needle valves. The flange is sealed by double silicone o-rings and can achieve max. the vacuum pressure of 10E-2 Torr by a quality mechanical pump and 10E-5 Torr by a molecular pump (vacuum pump is not included, please order separately). One digital vacuum gauge is installed on the top flange. Precision anti-corrosion digital vacuum gauge is in standard package |

| Heater and Sample Holder | Two independently controlled heaters with manually adjustable gap from 2 – 30 mm. 20 pcs Halogen lamps are used as the heating element for rapid thermal processing. Heaters are made of stainless steel with water cold jacket to reduce heat radiation and are capable of fast cooling. 5″ Dia. the circular wafer holder is built into the top heater for holding the substrate. One set of high thermal-conductive AlN plates (5″ Dia.×0.5mm Thick) are included (place on the back of the substrate to make it heat uniformly). A 58L/min circulating water chiller is included for saving water source. Top sample holder is rotatable at adjustable speed 0-7 RPM |

| Temperature Controller | Two precision digital temperature controllers with 30 segments programmable offer independent controlling of top and bottom heaters. Each controller has a PID autotune function to protect heaters from overshooting and an alarm function to prevent overheating from damaging the thermal couples. PC communication interface & software are installed for recording temperature profile. |

| Working Temperature | Maximum temperature for each heater: ≤ 800ºC. Maximum temperature difference between two heaters: ≤ 300℃ depends on the spacing between two heaters: Spacing 30mm Max. temp difference: 315℃ heating bottom only |

| Heating & Cooling Rate | Heating: < 8℃/s ( heating single heater only) Cooling: < 10℃/s (600 – 100℃) Max. |

| Thermal Couple | Two K-type thermal couples are installed on top and bottom heaters separately. |

| Working Voltage | 208 – 240VAC, single phase, 50A air breaker |

| Power Requirement | 10 KW total |

| Warranty | One year limited with lifetime support (Consumable parts such as quartz tube and heating lamps are not covered by the warranty). |

| Application Notes | The tube furnaces with quartz tube are designed for using under vacuum and low pressure < 0.2 bars / 3 psi / 0.02 Mpa. Vacuum pressures may only be safely used up to 1000°C. The flow rate for gasses should be limited to < 200 SCCM (or 200 ml/min) for reducing thermal shocks to the tube. |

Looking for "NST Two Zones CSS Furnace With Rotating Wafer Holder" ?

Piece

Explore More Products